Optimisation and redesign of a microfluidic lab-on-chip Dean spiral for size-based cell sorting

This investigation was done as part of a lab-based project over a Undergraduates Research Opportunities Programme summer placement and continued into an MEng project.

Microfluidic particle sorting techniques are a vital tool for cancer research as it paves the way for rare-cell isolation. A particle suspended fluid travelling through a confined space will experience Dean drag, pressure forces and a net inertial lift force. Lab-on-chip devices based on microfluidics take advantage of this to sort cells as their morphology, size and density determine the balance of these forces. As cancer cells are believe to exhibit different physical characteristics to healthy cells, research into these sorting devices could be key in distinguishing cell types for diagnostic applications.

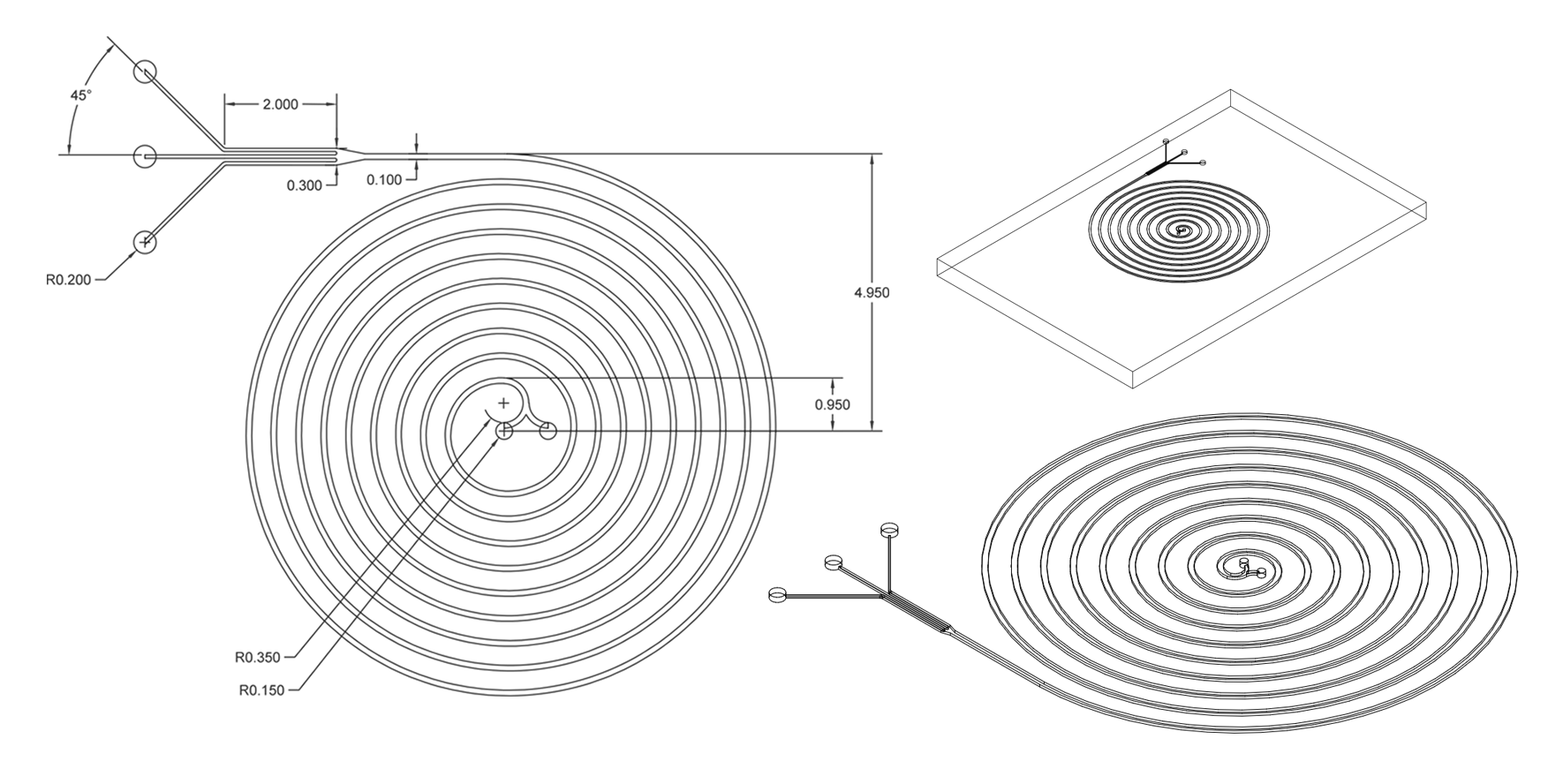

The project involved the investigation of an existing, commercially available microfluidic spiral, known as a Dean spiral, to sort particles of different sizes and improve the design for better sorting efficiency and particle recovery. Experiments in the lab were conducted to sort yeast cells from polystyrene spheres of various sizes to determine the efficiency of sorting by difference in diameter and density.

The efficiency and effectiveness of the size-based sorting is also affected by factors such as fluid flow rate and the geometric constraints of the Dean spiral e.g. number of turns and size and aspect ratio of the channel. To improve the design of the spiral based on my range of particle sizes, CAD modelling and computational fluid dynamics (CFD) was used to simulate the Dean spiral with altered dimensions.

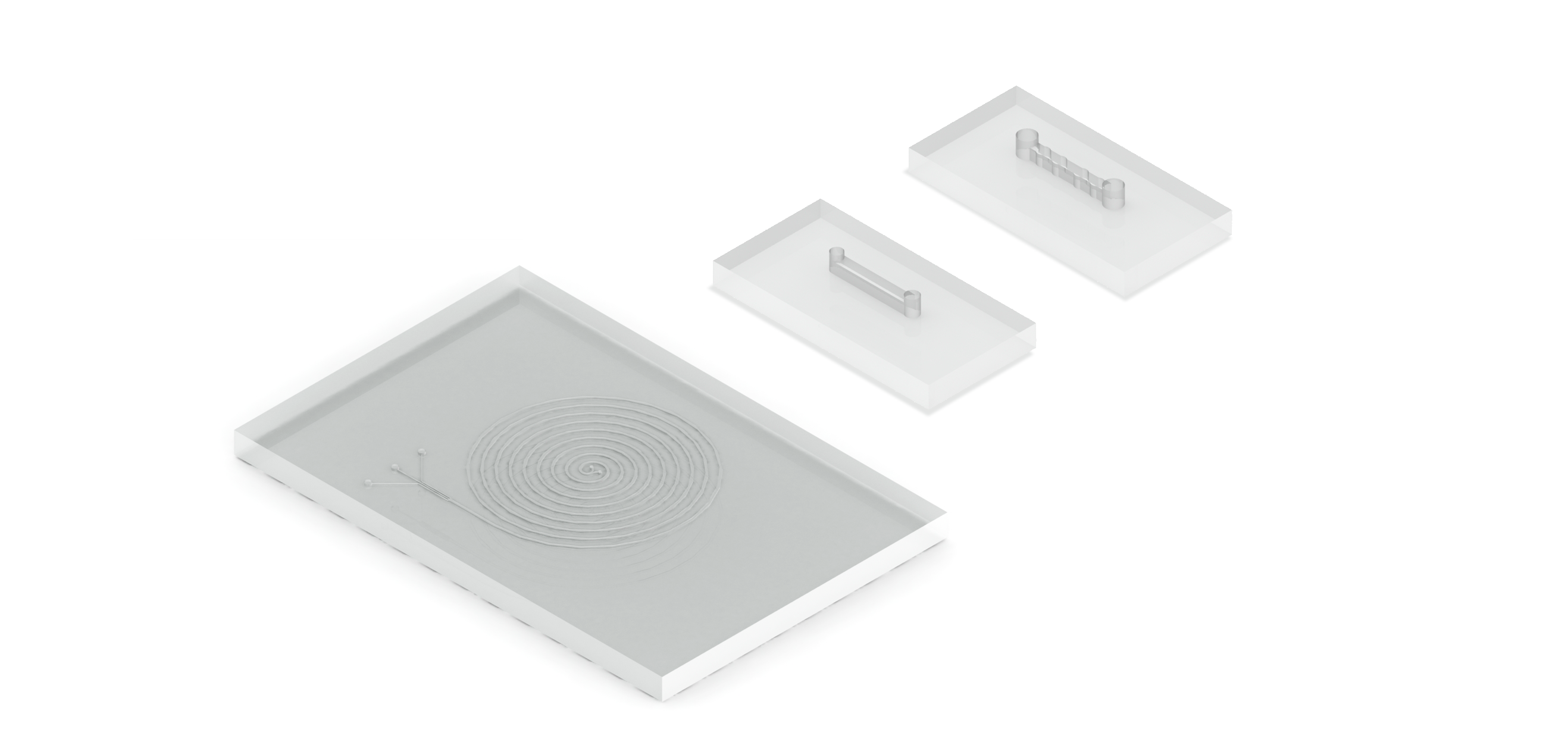

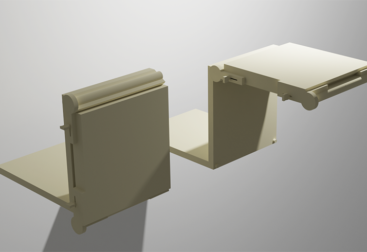

The scale of lab-on-chip devices and Dean spirals makes fabrication tricky as dimensions are usually in the range of 100 microns. Plastic moulding using 3D printed negative moulds resulted in low quality channels with ill-defined dimensions as a difference in a few microns drastically changes the forces experienced by particles flowing through the channels. 3D printing the channels themselves could offer high resolution channels so the redesigned Dean spirals and various other channel designs were modelled for fabrication using 3D printing.