PhD work at Imperial College London: a measurement system for high-frequency characterisation of graphene

In addition to the graphene sensor measurement system, I also designed and made a measurement system for the high-frequency characterisation of graphene (on high resistivity substrates).

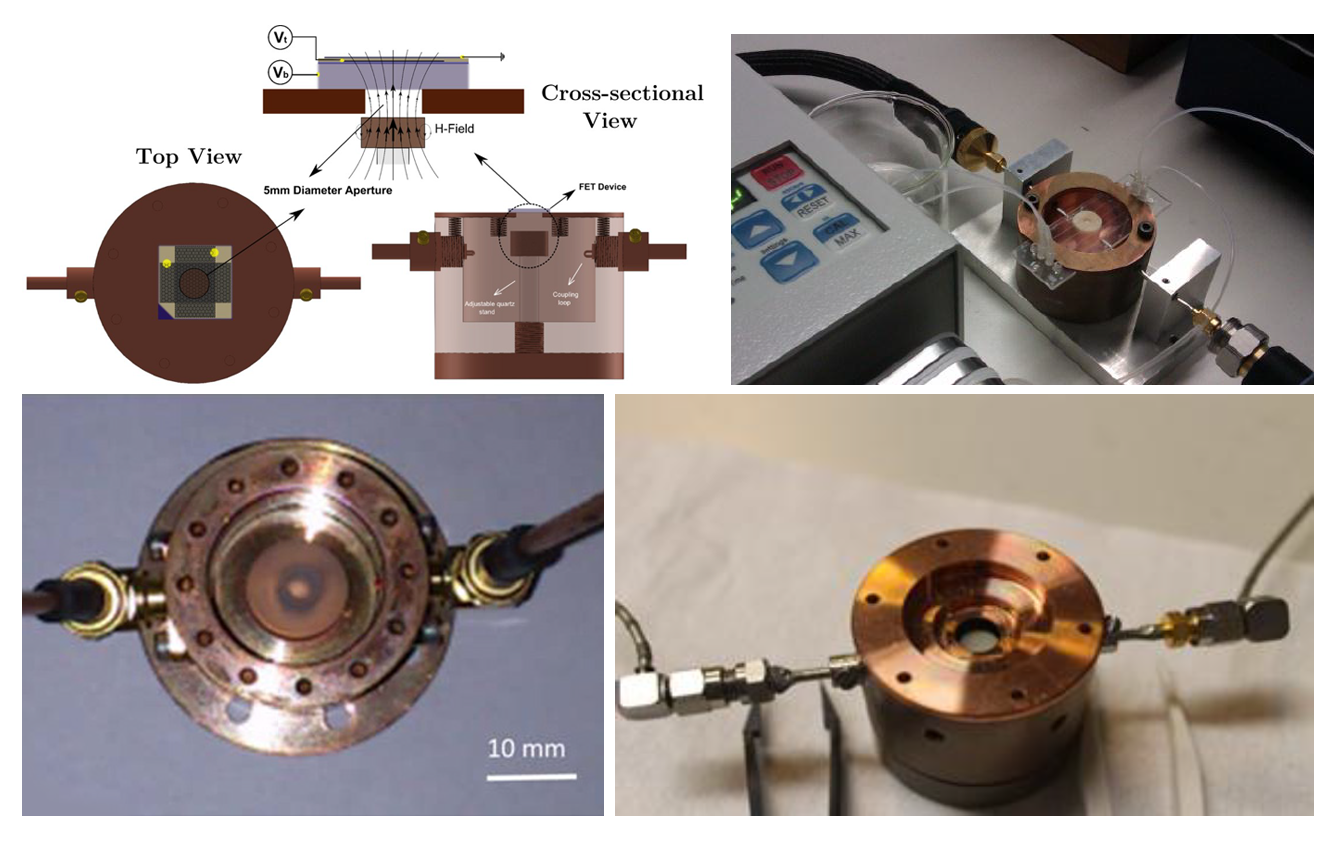

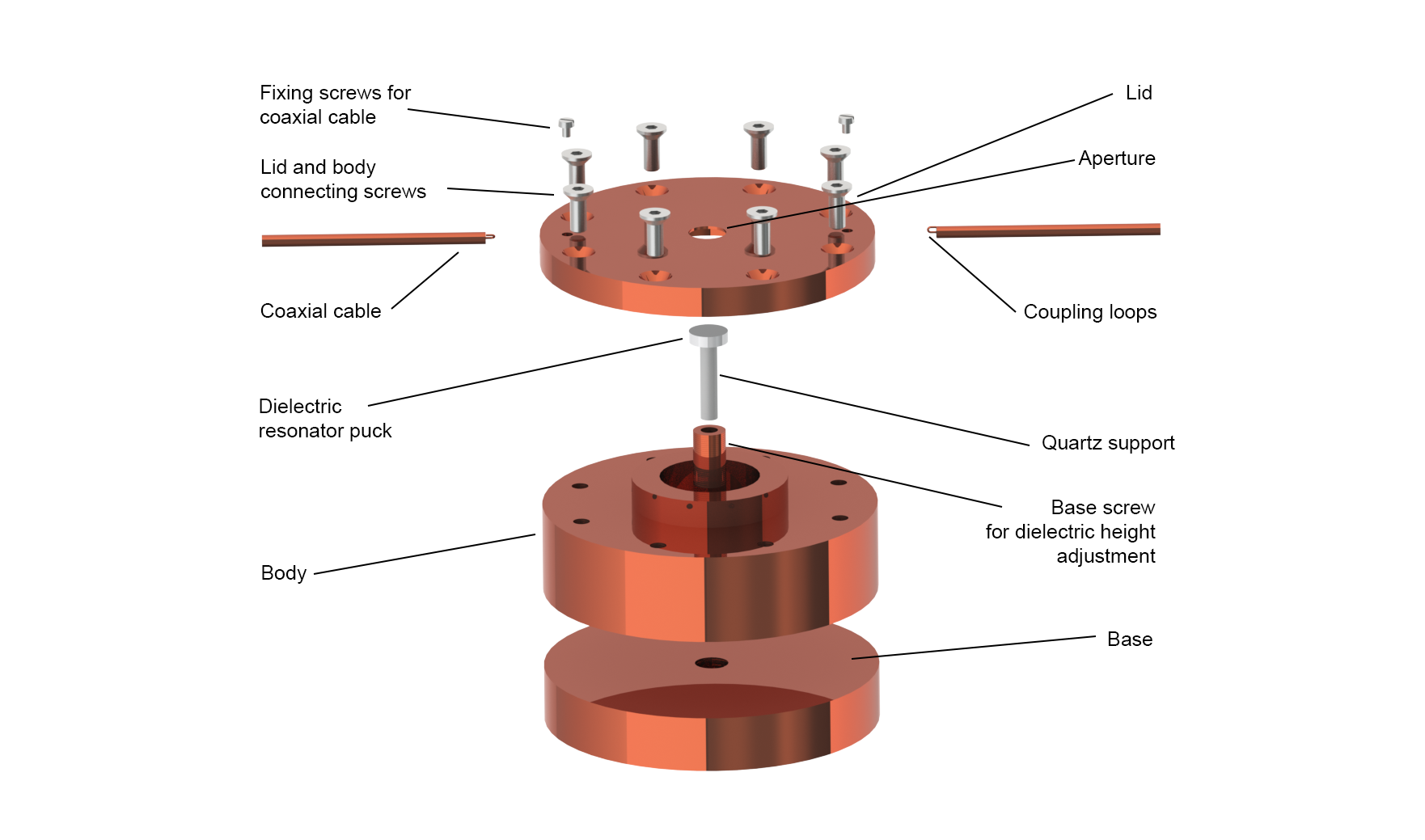

A dielectric resonator is at the core of the cavity and resonates in response to a high frequency microwave (1 – 1000 GHz) signal that can be applied using coaxial cables and coupling loops. As the dielectric resonates, it generates and electric and magnetic field and different resonant modes, which are present at different resonant frequencies, are used to describe the orientation of these fields. I looked at the TE01d mode which is known as the ‘fundamental’ mode of the system. When material interacts with these fields, changes in the resonant frequency and quality factor (a ratio of signal bandwidth) occur which can be used to charatcerise material properties like conductivity. However, for this to work the dielectric must be housed in copper shielding which contains the electromagnetic fields and specific material interaction can be implemented using an aperture that the fields can ‘leak’ out from.

To design the cavity, I had to used FEM analysis to model and simulate the electric and magnetic fields and determine the resonant frequency. This is dependent on and optimised by geometric parameters such as: dielectric resonator shape, size and aspect ratio as well its distance from the aperture and aperture size.

Below are some of the existing cavities and designs in our lab:

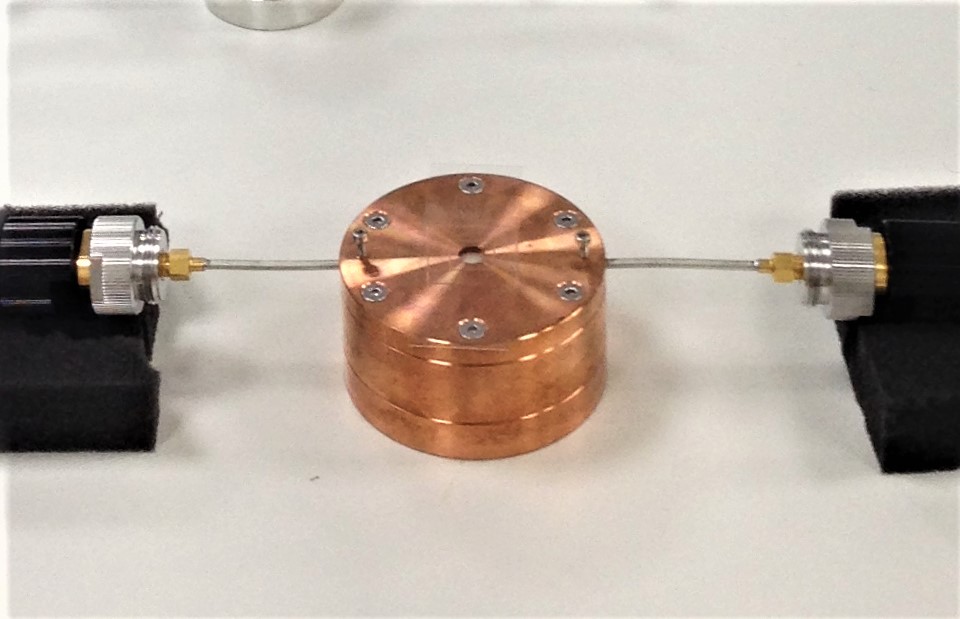

Once simulated and appropriately dimensioned, the copper cavity was made by CNC machining and used in the lab. Compared to previous cavities, design changes included cavity had a thicker top lid to better shield the electromagnetic fields, a smaller dielectric puck with dimensions that resulted in a resonant frequency around 9.5 GHz and etched squares on the lid for accurate sample placement.